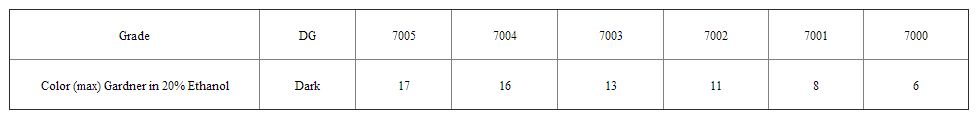

The resinous secretion of a tiny insect called Kerria Lacca is basically Natural Resin Lac. Once Natural Resin Lac is refined it is commonly known as Shellac. Shellac in available in different standards of quality and specifications. Shellac’s quality and specification purely depends on two main things.

At our manufacturing unit, Shellac is manufactured from the best quality raw material and by using the best process in the market. We use solvent extraction system through activated carbon in order to get the best quality Shellac for our clients. Now, let us have a quick look at some important physical data in regards to Shellac:

Common for all Grades

| Acid No. | (Dab9) | 68 - 79 | |

| Arsenic | (Dab9) | Max ppm | 1.5 |

| Ash | (Dab9) | Max % | 0.2 |

| Insolubility in hot alcohol | (Dab9) | Max % | 0.1 |

| Melting range | (Dab9) | °C | 77 - 90 |

| Loss on drying | (Dab9) | Max % | 2.0 |

| Specification No. | (Dab9) | 199 - 230 | |

| Wax | (USP XXIII) | Max % | 0.2 |

| Rosin | Nil |